| Material Type |

Grade |

Features |

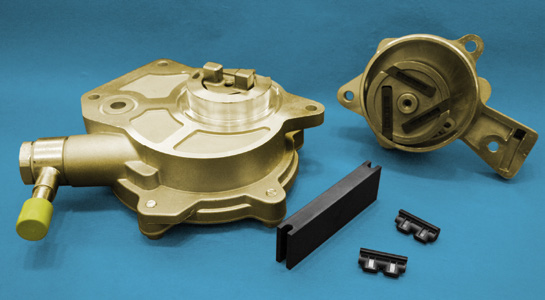

| PEEK Low Friction and Wear Resistant Grade Particles |

VICTREX™ PEEK POLYMER AS110 |

Natural color, semi-crystalline reinforced, injection molding, easy fluidity grade, balanced strength, creep resistance, toughness, and wear performance against light alloys over a wide temperature range, comparable to hard wear-resistant materials, good resistance to fluid chemical media. |

| VICTREX™ PEEK POLYMER 150FC30 |

Black, 30% carbon fiber, graphite, PTFE filled, injection molding, easy fluidity, suitable for complex cross-section parts and thin-walled parts, low friction coefficient, wear resistance, low linear expansion coefficient, excellent chemical resistance. |

| VICTREX™ PEEK POLYMER 150FW30 |

Black, semi-crystalline, 30% carbon fiber, PTFE filled, injection molding, easy fluidity, suitable for complex cross-section parts and thin-walled parts, low friction coefficient, wear resistance, low linear expansion coefficient, excellent chemical resistance. |

| VICTREX™ PEEK POLYMER 450FC30 |

Black semi-crystalline, 30% carbon fiber, graphite, PTFE filled, injection molding, standard fluidity, low friction coefficient, wear resistance, low linear expansion coefficient, excellent chemical resistance. |

| VICTREX™ PEEK POLYMER 450FE20 |

Natural color semi-crystalline, 20% PTFE filled, injection molding, extrusion, standard fluidity, low friction coefficient, wear resistance, excellent chemical resistance. |

CN